Electrozinc CM75 Wire Cable Tray

Width:

50MM 75MM 100MM 150MM 200MM 250MM 300MM 350MM 400MM 450MM 500MM 600MM 700MM 800MM 900MM 1000MM

Diameter(3.5mm~6.0mm):

3.5MM 3.8MM 4.0MM 4.5MM 4.8MM 5.0MM 5.5MM 6.0MM

Product introduction

1. Technical parameters

| Product Name | CM75 wire cable tray |

| Type | wire cable tray |

| Design | Straight-wire edge |

| Brand | Vichnet |

| Place of Origin | Zhejiang, China |

| Material | Q235 steel |

| Surface Finish | Electro-galvanized |

| Finish Thickness | EZ>12μm |

| Color | Zinc |

| Safe work loading | BS EN 61537:2007 Cable Management Clause 10.4 |

| Welding Strength Tests | Min breaking force 1166N |

| Guarantee | 10 years |

| OEM service | Available |

| Nearest Port | Ningbo, China |

| Monthly output | 500K meters |

| Sample order | Available |

| HS Code | 73089000 |

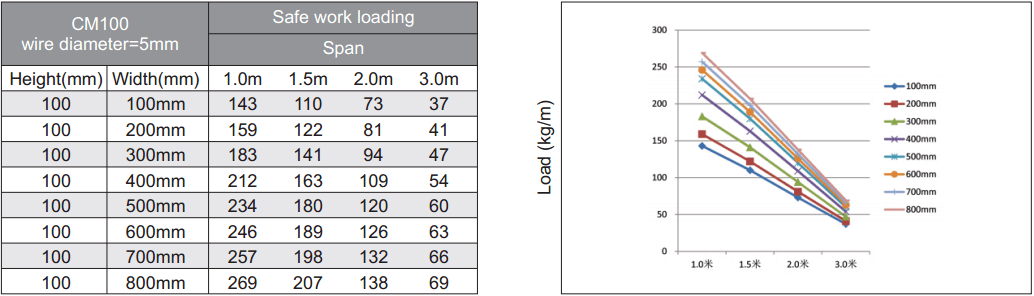

2. Loading capability of Vichnet wire baskets(Kg/meter)

CM100(height=100mm,wire diameter=5mm)

3. Vichnet Advantages

For wire mesh cable tray, we promised:

★ Vichnet is the only Manufacturer certificated with UL CE for Wire Mesh Cable Tray in China.

★ 10 Years warranty for Wire Mesh Cable Tray and Optical Fiber Cable Tray.

★ ISO9001, GMC approved management system for Wire Mesh Cable Tray.

★ The appointed supplier of Google, Microsoft, SIEMENS, ADM, COCACOL.

★ The first Wire Mesh Cable Tray manufacturer applied MFDC for welding.

★ Customers spread over 100 countries, even in Japan market.

Advantages for EZ wire mesh cable tray

★ We draw down 8mm wire to 5mm to smooth and strengthen the wire.

★ There is no tolerance of our tray size and wire diameter.

★ Our zinc coating is non-toxic and 12μ up, surface uniform.

★ Environmental protection, and it can be passed Rohs test.

★ Most of our clients come to us from other suppliers because the powder coating quality problem.

4. Problem

Why the EZ wire mesh cable tray have get rusty ?Because the get rusty cable tray have less than 5um zinc coating ,but Vichnet EZ wire mesh cable tray more than 12um zinc coating.

5. Story

Data Center of wire cable trays is a facility used to house computer systems and associated components, such as telecommunications and storage systems. It generally includes redundant or backup power supply, redundant data communications connections, environmental controls (e.g., air conditioning, fire suppression) and various security devices.The hospital & Leisure industry has undergone substantial change in recent years, with a strong shift towards high- end, heavily serviced buildings where concepts of quality, value, sophistication and branding are key to success.

Effective data center operation of wire cable trays requires a balanced investment in both the facility and the housed equipment. The first step is to establish a baseline facility environment suitable for equipment installation. Standardization and modularity can yield savings and efficiency in the design and construction of telecommunications data centers.

Standardization means integrated building and equipment engineering. Modularity has the benefits of scalability and easier growth, even when planning forecasts are less than optimal. For these reasons, telecommunications data centres used wire cable trays should be planned in repetitive building blocks of equipment, and associated power and support (conditioning) equipment when practical. The use of dedicated centralized systems requires more accurate forecasts of future needs to prevent expensive over construction.

- Posted by

admin

admin - Posted in

Jul, 24, 2015

Jul, 24, 2015 Comments Off

Comments Off

(66) 02-237-1807

(66) 081-255-2622

(66) 02-237-1807

(66) 081-255-2622

Join Us On Facebook

Join Us On Facebook Join Us On Twitter

Join Us On Twitter Join Us On In.com

Join Us On In.com Subscribe to Our Blog

Subscribe to Our Blog